Vermont Castings’ manufacturing plant is a long, narrow, forest-green building along a railroad line on the outskirts of Bethel. On a recent weekday, the facility, in which 125 employees paint, assemble and finish high-end woodstoves and gas grills for shipment worldwide, was literally humming with activity. You could hear it from the parking lot, where two tractor-trailer trucks were backed up to loading docks.

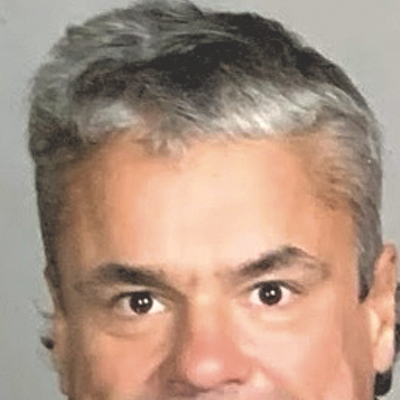

The industrial bustle signals a dramatic turnaround for Vermont Castings, which just last summer was on the brink of bankruptcy and faced a $102 million debt. Chief Financial Officer Ricardo León since convinced the company’s owner, a private equity firm called the Riverside Company, to write off its obligations, so 42-year-old León, along with three others in top management, could purchase the company outright. The entrepreneurial manuever saved nearly 200 jobs in Vermont.

Today, Vermont Castings is not only in business but largely debt-free. It’s also reversing a labor trend that for decades dominated American durable-goods manufacturing: The company is bringing overseas jobs back to the United States.

Robert Aitken mixes the enamels that give Vermont Casting’s woodstoves and grills their smooth and glossy veneer. The 49-year-old Vermont native said the plant is definitely busier than it’s been in years. “We’ve had our rough times in the past,” said Aitken. “Hopefully, the economy is turning around and people will buy our higher-end stoves.”

Rick Grant, the Bethel plant’s general manager, confirmed Aitken’s impression of the company’s growth — but declined to release any sales figures. Grant, who’s been with Vermont Castings for 12 years, said his staff was “very nervous” about the company’s future before the purchase was announced on July 31. But León, now CEO of Vermont Castings Group, has visited Vermont every month since, in part to inform his employees about where the business is headed. Although top managers for Vermont Castings Group are still based mostly in Paris, Ky. — where the company’s two prior owners were headquartered — much of its manufacturing is now back in Vermont.

In fact, Grant added, nearly every corner of his 160,000 square-foot manufacturing floor has been put into production. That’s partly because all of the company’s grill-assembly work, which was previously being done in China and Mexico, has been relocated to Bethel.

A high-tech laser cutter, which Vermont Castings purchased a few years ago, also enabled the company to bring all of its sheet-metal fabrication back from China. The laser cutter now runs around the clock, producing not only steel stoves but also parts for the grills.

“Between the grills and the stoves, our volume is the highest it’s been since I’ve worked here,” Grant added.

Operations are also bustling a few miles up Route 12 at the company’s foundry in Randolph, one of the last remaining cast-iron foundries in North America and the only one owned by a stove manufacturer. Plant manager Bob Wright, who’s been with Vermont Castings since the foundry was built in 1979, said it’s been an “exciting season” for him and his 75 employees.

“I’ve seen a lot of the cycles the company has been through,” Wright said, “but from my point of view, this is one of the best scenarios we’ve had in quite some time.”

According to Wright, the foundry pours about 3,500 molds per day of molten iron into cast-iron products and parts of various shapes and sizes; nearly all are made from scrap iron recycled from automobile wheels and drums. Some are recast into parts for Vermont Castings woodstoves. Others are products made for other companies, such as Lodge, a Tennessee-based cookery firm that sells cast-iron pots and skillets.

Over the years, the Randolph foundry has produced everything from cast-iron stadium seats to sinks, lavatories and electric hand dryers.

Vermont Castings sparked a revolution in woodstove designs in the early 1970s. Before then, most were big, sooty, inefficient potbelly furnaces likely to be found in rural farmhouses. The founder of Vermont Castings, Duncan Syme, reimagined the functional heat sources as the clean, efficient, attractive hearths people congregate around today.

Recalled Al Wilker, who designed woodstoves for Vermont Castings back in the 1980s: “Duncan’s shtick, being an artist, was if we could make a stove that looks like a piece of furniture, that might be our niche.”

They succeeded. First sold through DIY magazines such as Mother Earth News, the company’s products became so desirable, a “customer appreciation day” attracted more than 10,000 stove owners to Randolph in the early ’80s, according to Wilker. In a December 2011 story, Paul Henninge, a Burlington-based industrial designer, told Seven Days that Vermont Castings “set the standard, and the rest of the industry has been playing catch-up ever since.”

Richard Wright, publisher and editor of the industry trade magazine Hearth and Home called Vermont Castings “probably the best brand in the industry.”

But, like many iconic companies, Vermont Castings has changed hands numerous times over the years. Some of those owners put profits over product design. As Wright put it, “A brand is like a child. You either take care of it or it goes to hell.”

In 2006, Vermont Castings’ then-parent company, Monessen Hearth Systems, was sold to Riverside. Two years later, the stock market crashed and new housing construction ground to a halt. So, too, did the market for woodstoves, grills and hearths. Although Riverside sank a lot of money in the company, Wright said, the timing of its purchase couldn’t have been worse.

The hearth industry has been slow to recover. According to Wright, industrywide sales of all hearth appliances — including woodstoves, pellet stoves, gas stoves, fireplace inserts and the like — peaked at 2.8 million units in 2006. Those sales figures coincided with rising prices for home heating oil, which went from a record low of 30 cents per gallon in February 1999 to a record high of $4.20 per gallon in July 2008. Wright estimated unit sales of all hearth products in 2013 will probably clock in at no more than 800,000 units.

Despite the slow growth in new home construction, the new management team at Vermont Castings Group sounded optimistic when asked recently about the company’s sales potential. Reached by phone, Jess Baldwin,?senior vice president of sales and customer service, said the company is once again refocusing on its signature brands — namely, high-end woodstoves, gas grills and fireplace inserts.

How did Baldwin’s new boss convince the company’s previous owners to write off a $102 million debt?

“It was actually a good deal for them, too,” Baldwin said, “because they wanted to walk away with no future liabilities.” Part of the agreement, Baldwin explained, was that the new buyer would accept all past and future risks associated with Vermont Castings — financial, product liability, employee and regulatory. León’s tenure as CFO afforded him the experience to evaluate the potential risk.

It hasn’t all been smooth sailing since the sale was finalized. In the months following León’s purchase, management had to, in Baldwin’s words, “bring their costs in line” by furloughing 111 jobs in Vermont, Kentucky, Mexico and Canada, mostly at the highest management levels of the company. But Baldwin emphasized that there were no other negative consequences for Vermont Castings’ rank-and-file workforce, such as cuts in wages, hours or benefits.

In fact, the greatest threat to Vermont Castings may be a regulatory one: This month the U.S. Environmental Protection Agency published new proposed emissions standards for all new woodstoves, pellet stoves, wood-fired furnaces and other residential heaters. According to the EPA, in some cities, such as Keene, N.H., wood combustion in winter contributes more than 50 percent of the daily fine particle emissions. The EPA estimates compliance could cost manufacturers between $16 million and $28 million a year.

“That’s going to put a really great hardship on manufacturers,” Baldwin said, “and our concern is that it’s going to put the price of stoves beyond the reach of most consumers.”

But Vermont Castings employees like Aitken appear to be in for the long haul.

“I bided my time for the three months to see what he was going to do with it,” Aitken said of León’s leadership. Aitken was committed enough to submit a cost-cutting idea that earned him a $25 bonus.

Another worker said the new management gave him a free turkey for Thanksgiving and a $35 gift card from Walmart for Christmas.

“Thirty-five bucks? That’s a new pair of boots,” Mike said. “Can’t beat that.”

The original print version of this article was headlined "On Fire"

Comments

Comments are closed.

From 2014-2020, Seven Days allowed readers to comment on all stories posted on our website. While we've appreciated the suggestions and insights, right now Seven Days is prioritizing our core mission — producing high-quality, responsible local journalism — over moderating online debates between readers.

To criticize, correct or praise our reporting, please send us a letter to the editor or send us a tip. We’ll check it out and report the results.

Online comments may return when we have better tech tools for managing them. Thanks for reading.