For the past five years, Seven Days has been printed northwest of Montréal at Québecor Media Printing. For our first-ever Québec Issue, senior multimedia producer Eva Sollberger followed the paper's trail from Burlington to the press in Mirabel and back, sharing the journey in her latest video episode of "Stuck in Vermont."

Sollberger spent a Monday and Tuesday at Seven Days' Burlington office, talking to writers, designers, proofreaders and editors about the process of making the weekly newspaper. Then she crossed the border into Canada with publisher and editor in chief Paula Routly. The two arrived in time to watch the fast-paced factory print 35,000 copies of the paper late on a Tuesday night. They returned to Burlington at 3 a.m. on Wednesday morning — just a few hours before a truck from the press pulled up to the Seven Days loading dock, full of freshly printed copies to be distributed across the state.

Sollberger spoke with Seven Days about filming the episode.

Well, this subject hits close to home!

Ha ha, indeed. I have been on the full-time staff at Seven Days for 16 years, but I work from home editing videos and don't often get to see behind the scenes of the making of the paper. It was a pleasure to document my coworkers' hard work, and I'm blown away by all the steps it takes to create one issue. The talent, teamwork and intense scrutiny that goes into every issue is mind-boggling. When you add in the state-of-the-art printing press and the precise processes for making and distributing 35,000 copies, I don't quite understand how we do this every week!

- Eva Sollberger ©️ Seven Days

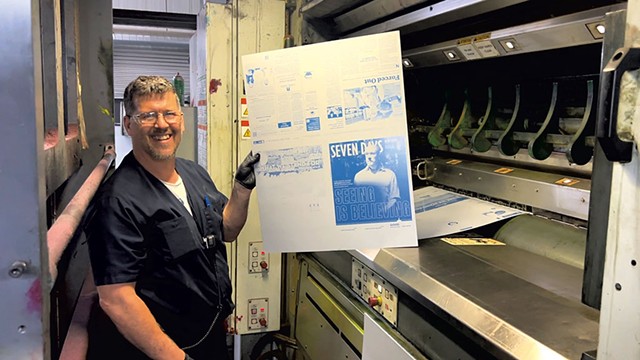

- François Ouellette holding a plate of Seven Days

How was the trip to Canada?

It was a rainy night, and my windshield wipers could barely keep up. There was also smoke in the air from the Québec wildfires; at times it was hard to see the road amid the haze of gray. A dirt road detour on Route 133 slowed us down quite a bit. That was after a Canadian customs official asked us a bunch of questions about why we were traveling to Mirabel late on a Tuesday night. It is always exciting driving over the elegant Samuel de Champlain Bridge and past the twinkling city lights of Montréal. Paula was a great copilot and made sure we found all the right exits.

The press was straight out of Willy Wonka & the Chocolate Factory!

I made a video at our former printer, Upper Valley Press in North Haverhill, N.H. (That was also an eventful late-night drive, and we almost hit a moose.) So I had a general idea of what printing presses look like. But nothing prepared me for the massive size and high-tech elements of this one. I felt wide-eyed like Charlie Bucket, amazed at every turn.

Everyone was very helpful and took the time to show us what they were doing. It was really loud, so our guides had to shout in our ears. Also there was a unique smell — a mixture of wet paper and chemical ink. Too bad this video is not in Smell-O-Vision.

The press itself is four stories tall, with a massive glass exterior. Rolls of paper the size of compact cars are stored in the lower level; beeping robots shuffle the rolls around to where they need to go. When Paula stood next to an imposing tower of paper and posed for the video, she looked so tiny! There are color-coded tubes snaking along the ceiling, leading to giant tanks of colored ink. You can't help but feel childlike wonder.

- Eva Sollberger ©️ Seven Days

- Paula Routly (left) and Eva Sollberger

What was it like to see Seven Days get printed?

We had to climb up high to get close to the four-color press that would print that week's issue — and to watch multiple press operators attaching the aluminum plates that apply the ink. I'm afraid of heights, and the last set of metal stairs gave me heart palpitations. We stood on the top level — which is called the "deck of the Titanic" — and watched the paper start rolling, first slowly, then faster and faster. We oohed and aahed.

Down below, a team of workers meticulously checked the paper, making sure the pages were properly registered and printing in the correct order.

Soon it was all whizzing past like a waterfall of images and words. The rolls are huge, and the paper has to be cut and folded down to size. We got to grab a finished copy, literally hot off the press, and I filmed Paula holding one. So much work went into those 104 pages of newsprint.

For the sake of the video, I asked Paula to yell "Stop the press!" the way they do in old journalism films. She went with "Arrêtez les presses!" and did an excellent job shouting at the paper as it thundered past.

What happened after printing?

We headed to a huge space where all the post-printing stuff happens. The papers come in on tracks along the ceiling, hanging from what looks like a moving clothesline. We watched in awe as they sped above our heads, twisting and turning like water. Another machine — or two — inserted the Hannaford flyers. Then papers were stacked and wrapped, placed on shipping pallets, and cocooned in plastic. A beeping bucket loader delivered the bundles to a loading dock and into the back of a 53-foot truck.

The entire process — printing and packaging — took a little more than an hour and a half. By the time Paula and I left at midnight, we were exhausted but energized by what we'd witnessed. I was back at the Seven Days loading dock by 6:30 a.m. the next morning to see the papers get distributed — another massive feat.

So many steps go into producing this newspaper and getting it into the hands of readers. In addition to a ton of elbow grease, I think there might be some magic involved. It makes me proud to be a part of the Seven Days team.

Why New England News Is Printed in Canada

- Eva Sollberger ©️ Seven Days

- Jasmin Grondin preparing a roll of paper

Giant rolls of newsprint feed fewer printing presses than they once did, back in the day when almost every adult in North America read a daily print newspaper. Many plants have closed or switched to making packing materials, complicating business for those publications, like Seven Days, that outsource their printing.

Yes, technology has made some things easier: Today digital files that contain the entirety of the newspaper can be transmitted electronically, with a push of a button, to a printer anywhere in the world.

But the actual act of printing hasn't changed much. While robotic devices assist with some of the heavy lifting, it's still a messy, laborious, deafening and dangerous job. Awesome, too.

In the case of a newspaper, the press has to be close enough to the circulation area to be able to turn the product around in a timely fashion. Read: After thousands of copies have been printed, inserted, stacked and wrapped, someone has to drive through the night — in all weather — to get them where they need to go.

No vendor is more important to a newspaper.

Since it started almost 29 years ago, Seven Days has done business with four different presses — longtime relationships built on reliability and trust. We loved them all and left only because they could no longer meet the needs of our growing paper. No printing facility in Vermont currently has the capacity to handle the job. In 2018, we found Québecor Media Printing across the U.S.-Canada border in Mirabel. Or rather, it found us.

Deciding whether to make the switch took some time. We had concerns about entrusting such a crucial part of our operation to an entity in another country. For example: Would the border present a problem, resulting in unexpected delays? Non, as it has turned out. Pas du tout. Even during the pandemic, when we couldn't visit Canada, the paper sailed across the border in the wee hours of every Wednesday morning. Numerous other Vermont media outlets have followed in our footsteps. At last count, Québecor was printing more than 30 New England newspapers and print products — and doing a bang-up job.

At Seven Days, it's a weekly reminder that we have more in common with our northern neighbors than Lake Champlain and maple syrup.

— P.R.

Comments

Comments are closed.

From 2014-2020, Seven Days allowed readers to comment on all stories posted on our website. While we've appreciated the suggestions and insights, right now Seven Days is prioritizing our core mission — producing high-quality, responsible local journalism — over moderating online debates between readers.

To criticize, correct or praise our reporting, please send us a letter to the editor or send us a tip. We’ll check it out and report the results.

Online comments may return when we have better tech tools for managing them. Thanks for reading.